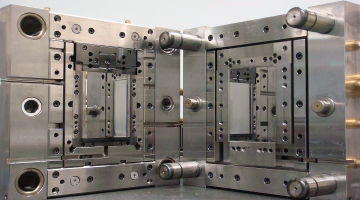

Precision molding

We provide high-quality products for the automotive, medical, and biotechnology fields, leveraging thin-wall mold/micro-transfer molding product technologies, in a quest for the limits of injection molding.

Since our founding in 1972, we have consistently grown our business with a dedication to precision production of both molds and components. Our basic stance on this issue has not changed.

We offer transfer of micro-patterns that is difficult for other companies to provide in molded products and can handle everything from prototyping to mass production of thin-walled products with precision.

PRODUCTS

Molded products for vehicles

Molded products for vehicles

Updated! Molded products for medical and bioscience

Molded products for medical and bioscience

Updated! Various precision-molded products, decorations, diffractive optical elements (DOE) Updated!

Various precision-molded products, decorations, diffractive optical elements (DOE) Updated!

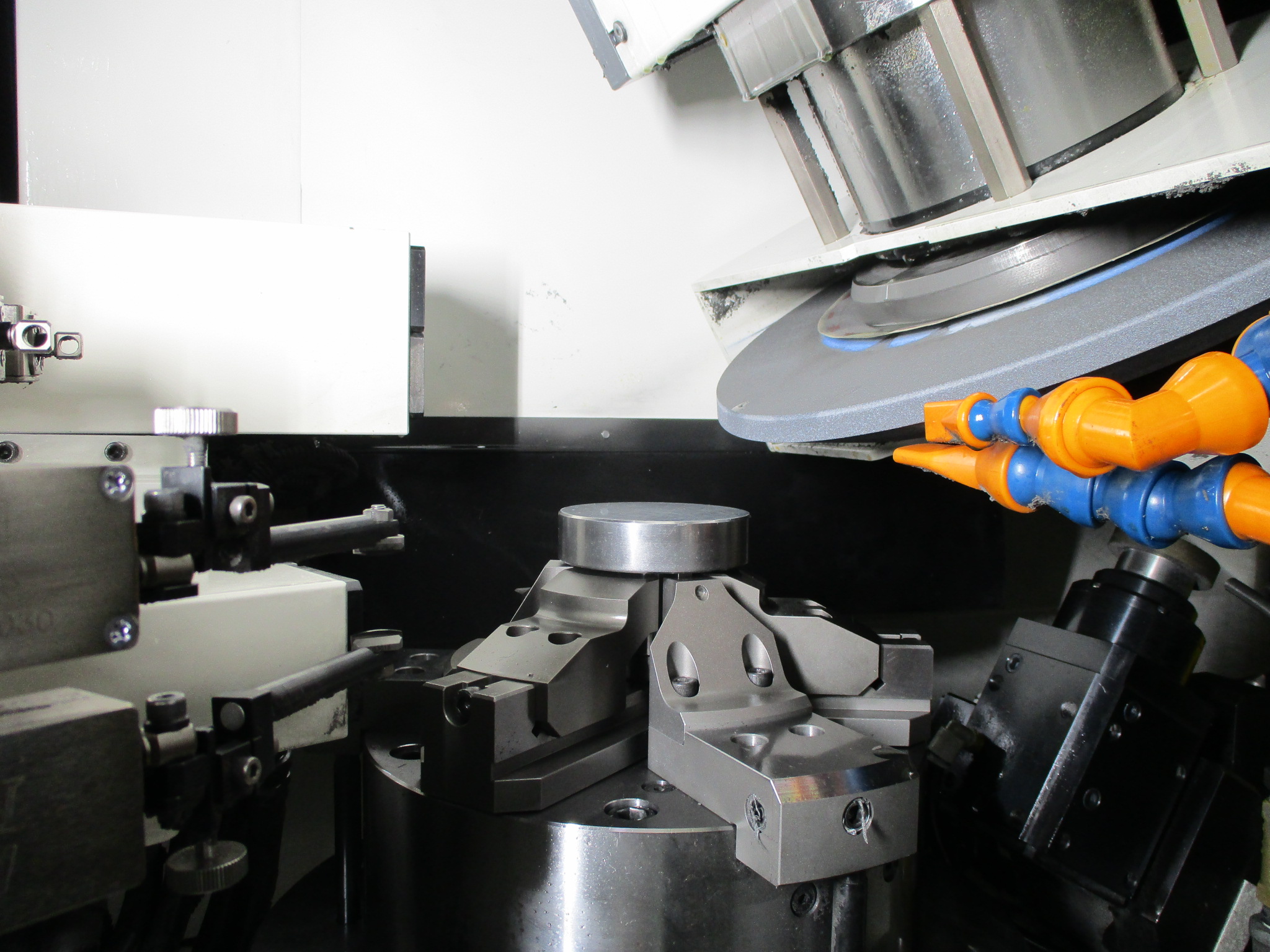

Precision processing

With our world-leading mold and precision processing technologies, we support customers' product development and productivity improvements.

We handle the manufacture of micron-order precision components based on our mold manufacture processing techniques and equipment.

We manufacture high-quality products one by one in a reliable manner in accordance with the designs of our customers. Moreover, in addition to machine precision we also use our comprehensive array of measuring instruments to provide dimensional evaluation.

We keep ourselves close to our customers so that we can hear their concerns and utilize our ultra-high precision molds and precision processing technology to help transform their ideals into reality.

PRODUCTS

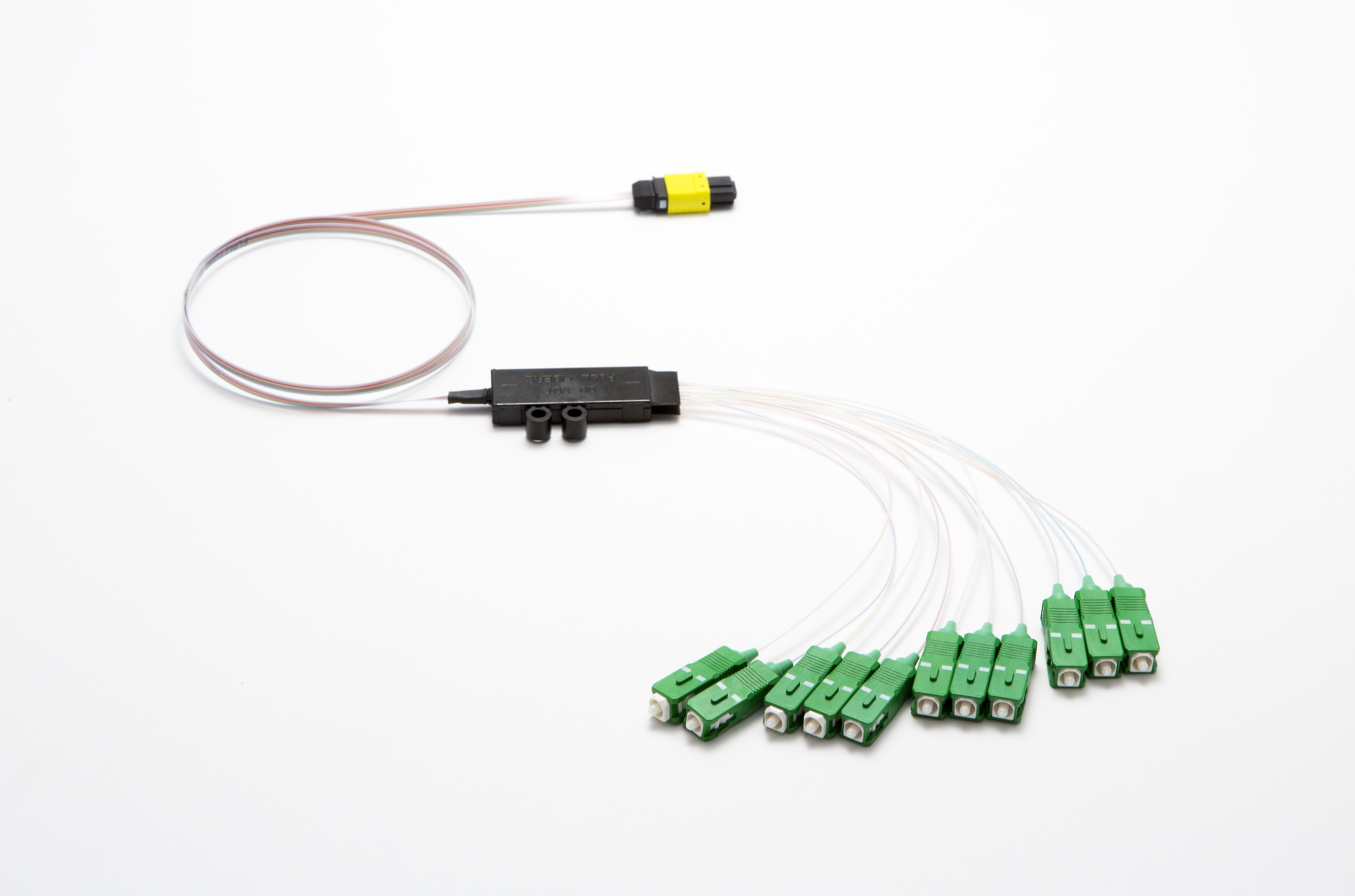

Optical Communications Components

Providing technologies and products for optical networks marked by small size, high speed, and large data volumes.

At Seikoh Giken, we manufacture optical communication components mainly using optical fiber materials for a diversity of applications. Optical communication components fulfill a variety of functions in various locations of optical communication networks created by telecommunications systems companies. Telecommunications service carriers deploy and operate these optical fiber networks to provide end users with convenient telecommunications environments.

PRODUCTS

Intelli-Cross® Pro

Intelli-Cross® Pro

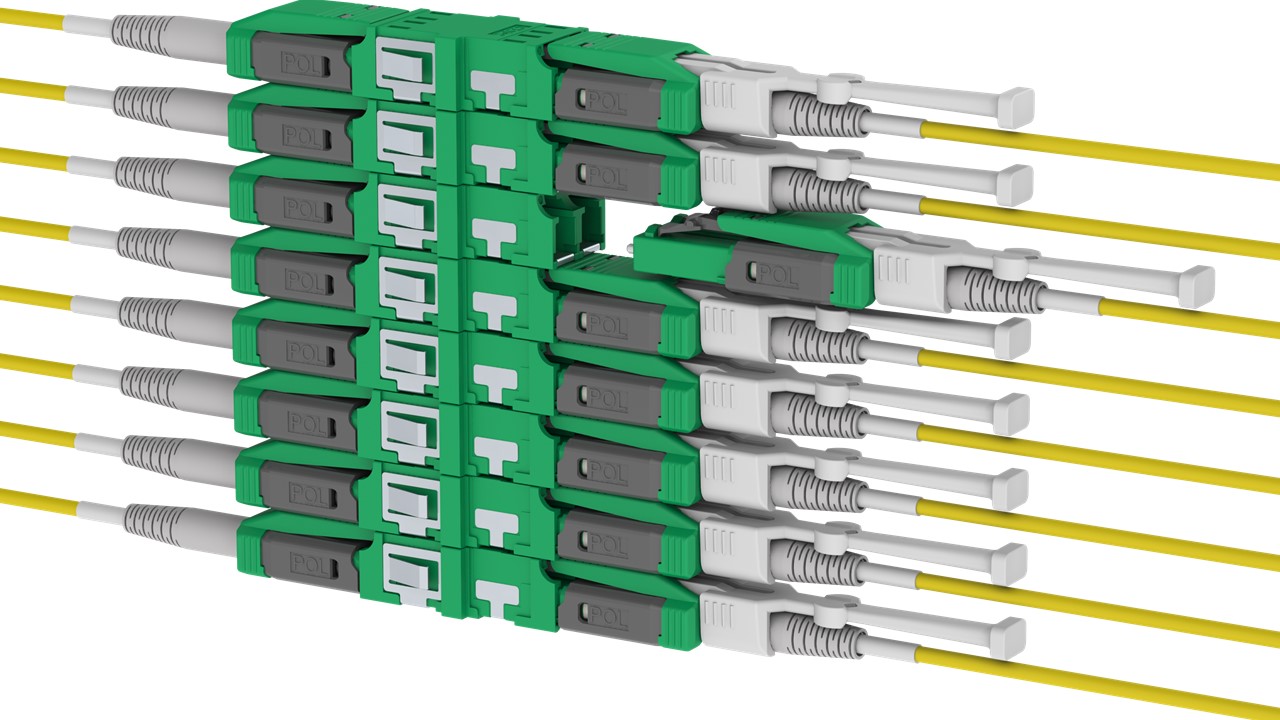

LC Uniboot Connector Connector

Connector Ferrule

Ferrule Adaptor

Adaptor Jumper cable

Jumper cable Optical Packaging Parts

Optical Packaging Parts Attenuator

Attenuator Crimping Tool

Crimping Tool

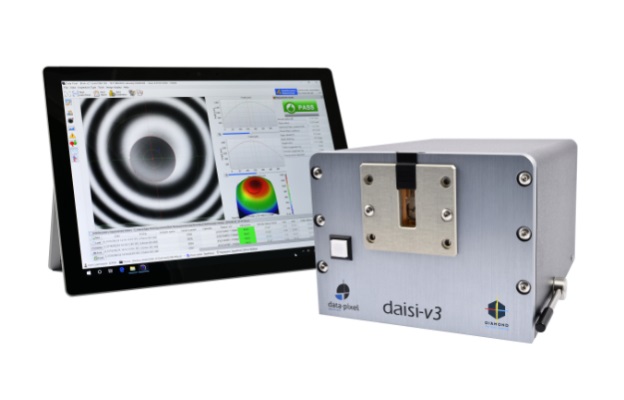

Equipment & Device

Centered on optical fiber polishing machinery, Seikoh Giken proposes process integration spanning the width from bonded anchorage required for jumper lead manufacturing lines to polishing and inspection.

Development of optical fiber related machinery and equipment

"There must be a more efficient method for polishing optical connector end faces." We have answered and resolved this customer requirement by developing machinery and equipment that grasp the characteristic properties of optical fiber.

PRODUCTS

Optical Mfg. Equipment

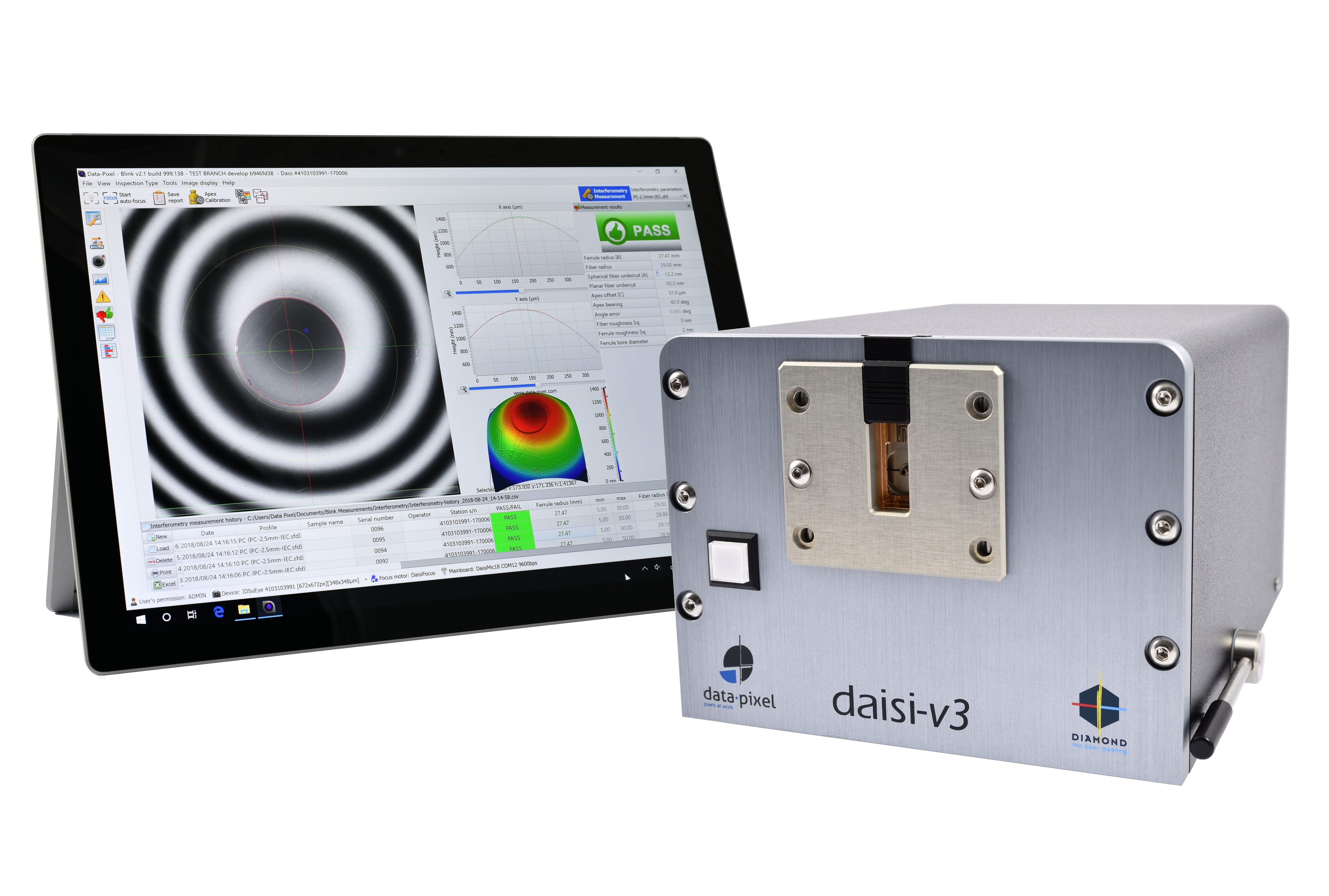

Optical Mfg. Equipment Interferometer

Interferometer Endface Cleaner

Endface Cleaner

Updated! Field Use Equipment

Field Use Equipment New Products

New Products

Updated! Products under development Updated!

Products under development Updated!

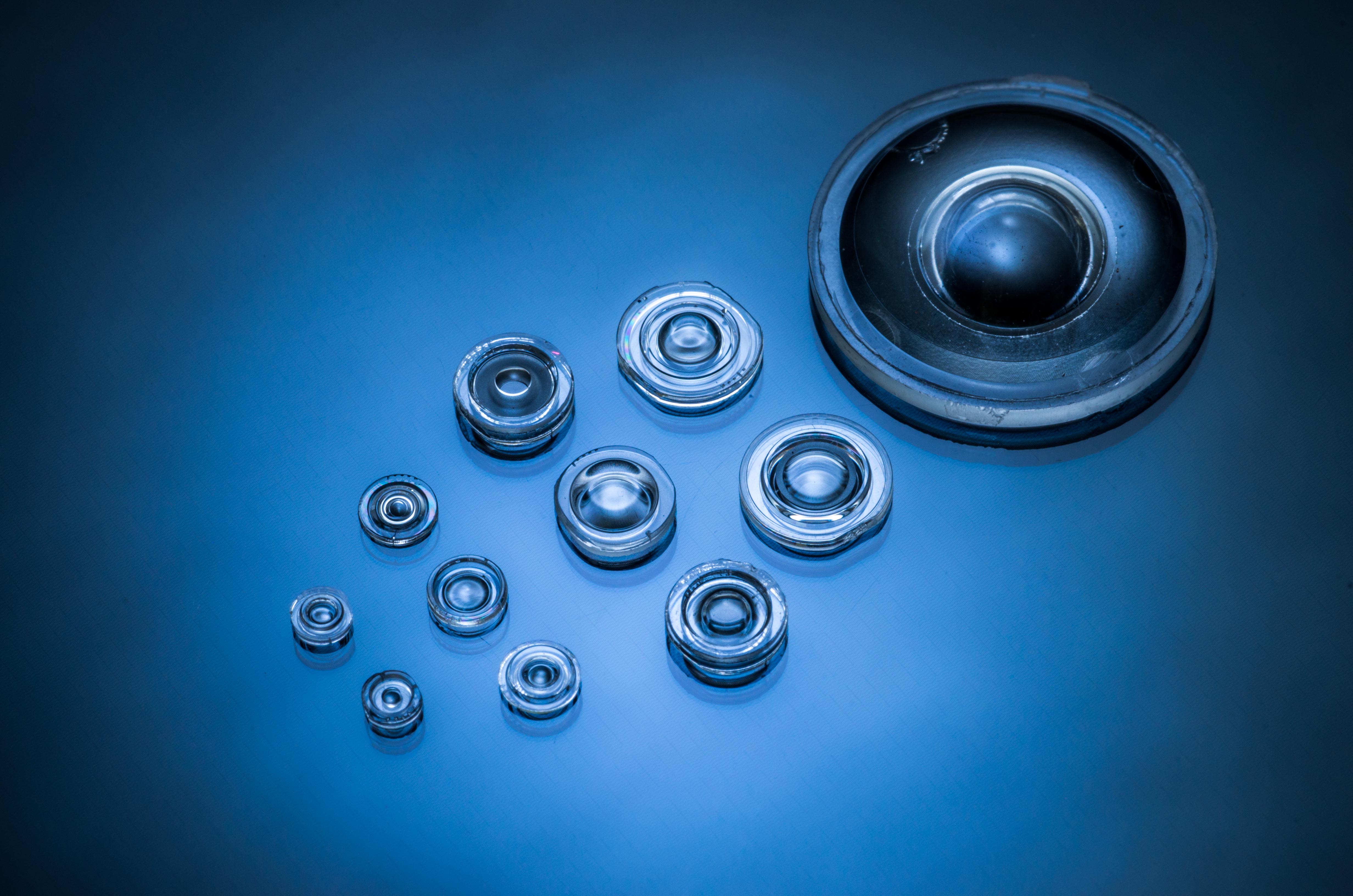

Lens

Making Clear Vision Ahead

Visualize the future through precision mold processing technology and innovative molding technology

While any type of item is improving functionality or accuracy in our life, we Sekoh Giken is providing high quality small form lens for camera and 3D sensors in smartphone, IoT device and medical equipment with using our precision processing technologies that we have cultivated since our company founded.

PRODUCTS

Device for RoF Application

We create unparalleled equipment with our Radio-over-Fiber technology.

The potential of optical measurement and optical transmission

"Show us something we have never seen before." "We have an intractable problem. Solve it for us." We have answered and resolved these customer sentiments with RoF enabled equipment.

PRODUCTS

Optical transmission equipment

Our optical transmission equipment can transmit all sorts of radio signals, including those of television, mobile phones, and GPS.

In accordance with our customers' needs, we offer the optimal systems using power-over-fiber and optical multiplexing technology.

Given that all sorts of information today are transmitted wireless and by optical fiber, their reliability and track record have earned the optical transmission equipment of Seikoh Giken an excellent reputation in the broadcasting infrastructure industry.Seikoh Giken is committed to addressing customers' entire needs, across the width from devices with high reliability requirements such as enhanced lightning protection to general purpose products.

Component processing

Component processing Precision measurement

Precision measurement Ultra-high precision molds

Ultra-high precision molds

Reflowable high temperature resistance Lens

Reflowable high temperature resistance Lens Far-infrared Lens

Far-infrared Lens

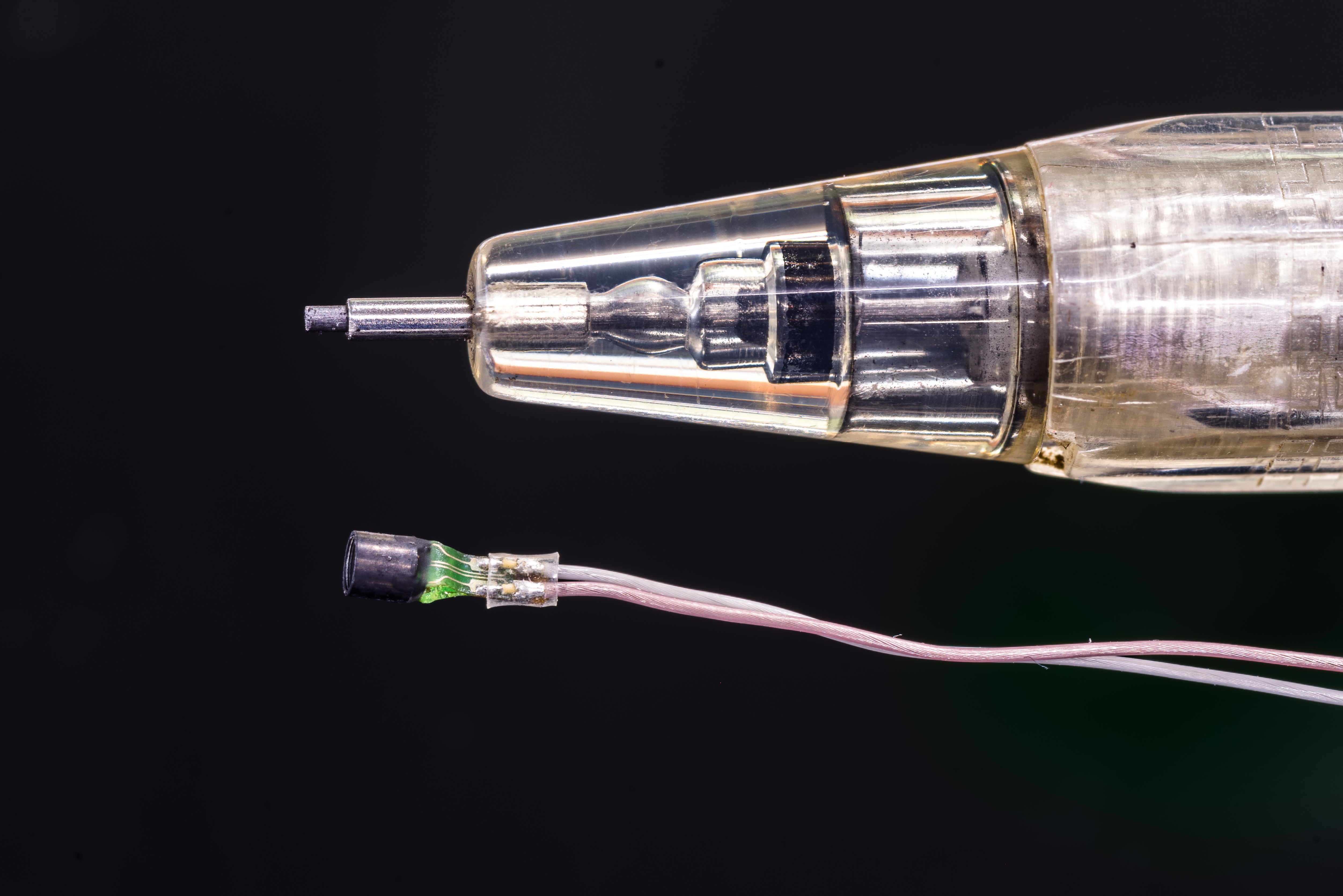

Isotropic optical E-field sensor head/Optical probe head

Isotropic optical E-field sensor head/Optical probe head OPTICAL PROBE for malfunction noise

OPTICAL PROBE for malfunction noise

Optical transmission equipment

Optical transmission equipment