PRODUCTS

Ultra-high precision molds

With our world-leading ultra-precise molding technologies, we support customers' product development and productivity improvements.

Precision molds of all kinds

For half a century since our founding, we have grown our mold business around the keyword, “precision.”

We engage in highly reliable mold production, basing our efforts on a track record of production of thousands of molds.

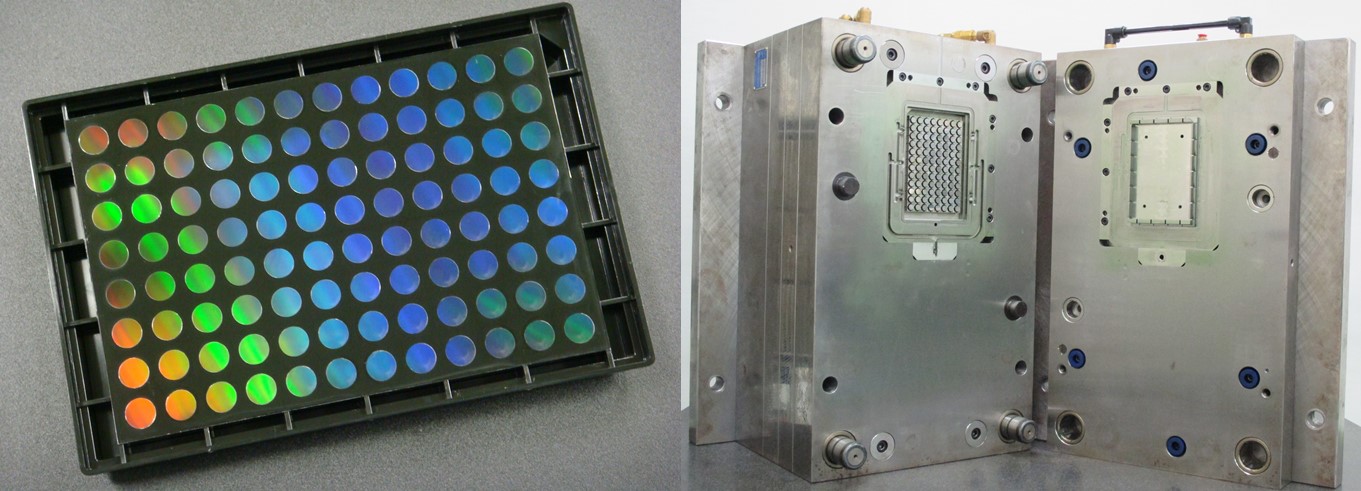

cell-culture-related molds

cell-culture-related molds

We handle production of molds for disposable products such as DNA chips and those used in cell culturing, as well as for consumable parts in medical equipment.

Molded products that require precision construction are handled based on in-house molds.

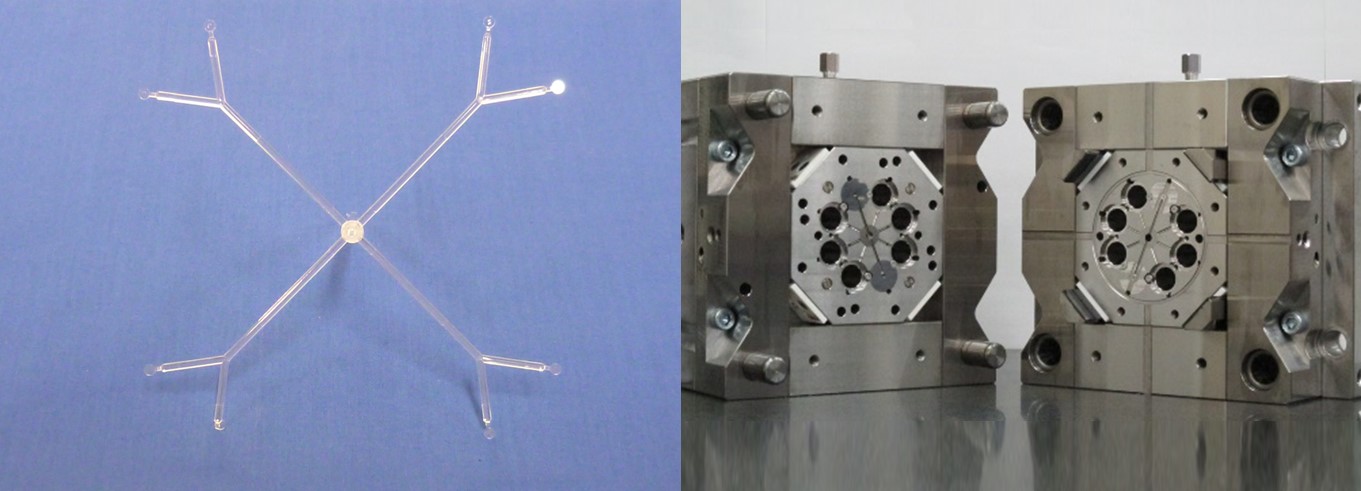

plastic lens molds

plastic lens molds

Temperature control allows us to handle everything from blank machining to machining of aspherical surfaces.

We use dedicated measuring devices to control tolerances down to the µm level.

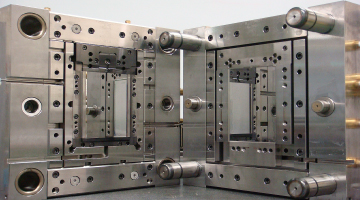

Ultra-high precision molds

Starting from the design stage, Seikoh Giken provides the fundamental tools underlying the creation of all precision molded products

We have implemented an integrated manufacturing system covering everything from mold material processing to quenching, polishing, and assembly, and manufacture a range of precision molds. We leverage molding technologies such as low temperature molding, thin-wall molding, and micro-transference, allowing us to promote mold manufacturing with the highest production efficiency, for long-term stable provision of molded products.

We have implemented an integrated manufacturing system covering everything from mold material processing to quenching, polishing, and assembly, and manufacture a range of precision molds. We leverage molding technologies such as low temperature molding, thin-wall molding, and micro-transference, allowing us to promote mold manufacturing with the highest production efficiency, for long-term stable provision of molded products.

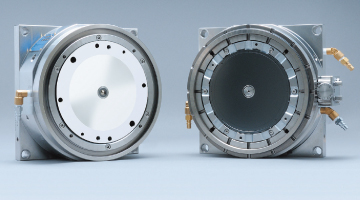

Molds for optical discs

Boasting an overwhelming global market share thanks to high production cycles and superior reproduction properties

Our molds for CD-Rs and DVDs have established a firm position as a global top brand on the merits of high molding quality regarding transferability, double refraction, and warping, etc., in addition to mold reproducibility, durability, and shortening, which are beyond the reach of competitor mold manufacturers. In 2008, we started selling molds for Blu-ray discs. Using our DVD know-how, we are working to further improve quality and achieve industry-leading high cycle times.

Our molds for CD-Rs and DVDs have established a firm position as a global top brand on the merits of high molding quality regarding transferability, double refraction, and warping, etc., in addition to mold reproducibility, durability, and shortening, which are beyond the reach of competitor mold manufacturers. In 2008, we started selling molds for Blu-ray discs. Using our DVD know-how, we are working to further improve quality and achieve industry-leading high cycle times.

Quality control systems

As digital appliances become smaller and thinner, the components comprising them grow more complex and detailed. Accordingly, the processing of the molds and metal parts used to mold the components also requires more precision. The Seikoh Giken Group proactively deploys the latest measuring devices to meet the challenging demands of our customers. We are equipped with a range of precision measuring devices, including high-precision three-dimensional measuring equipment. Additionally, we gained the trust of our customers through our quality control system, which is in line with international certification ISO9001.

As digital appliances become smaller and thinner, the components comprising them grow more complex and detailed. Accordingly, the processing of the molds and metal parts used to mold the components also requires more precision. The Seikoh Giken Group proactively deploys the latest measuring devices to meet the challenging demands of our customers. We are equipped with a range of precision measuring devices, including high-precision three-dimensional measuring equipment. Additionally, we gained the trust of our customers through our quality control system, which is in line with international certification ISO9001.

Inquiry by telephone:+81-47-386-3111

(Industrial machinery - Sales manager)

Mon~Fri 8:30~17:30

PAGE TOP