PRODUCTS

Precision processing

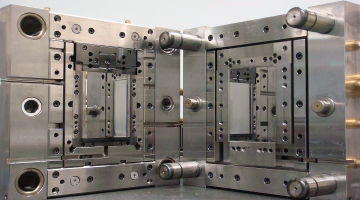

With our world-leading mold and precision processing technologies, we support customers' product development and productivity improvements.

We handle the manufacture of micron-order precision components based on our mold manufacture processing techniques and equipment.

We manufacture high-quality products one by one in a reliable manner in accordance with the designs of our customers. Moreover, in addition to machine precision we also use our comprehensive array of measuring instruments to provide dimensional evaluation.

We keep ourselves close to our customers so that we can hear their concerns and utilize our ultra-high precision molds and precision processing technology to help transform their ideals into reality.

Integrated production systems, quality control (ISO9001-certified)

We offer integrated production, handling everything from material procurement to heat processing, cutting, grinding, measurement, and packaging.We also have a proven network able to handle wide range of surface treatments. Moreover, we back up our quality assurance guarantee with a range of measuring instruments, centered around ultra-precise measuring devices controlled in a constant temperature, constant humidity environment.

Super-and ultra-high-precision processing technology capabilities

Working from the techniques and experience gained through the thousands of molds that we have made since our founding, we assign an experienced veteran (skilled works: internal regulations) to each process and apply strict quality control to our product manufacturing.In our manufacturing system, artisanal skills are passed on to young workers who are then encouraged grow further, ensuring a long-term, stable supply of goods.

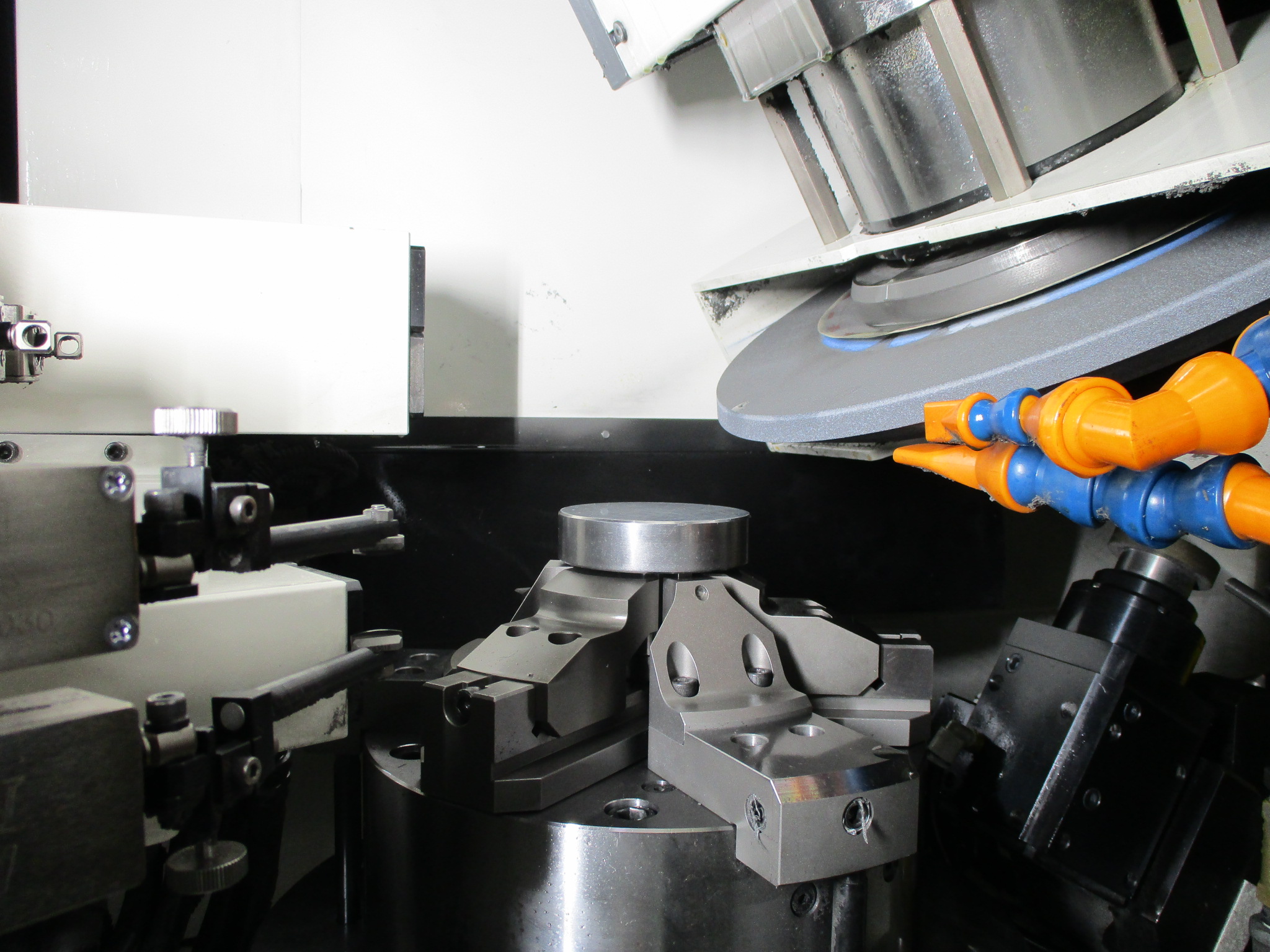

Grinding process

Our track record in manufacturing molds for optical disc injection molding has given as a wealth of experience in machining round shapes such as cylinders and cylindrical objects.We have a record of many successes with roundness and circumferential deviation of less than 0.003 mm and can also have our artisans hand-finish and lap products.

Additionally, we have an extensive array of grinding tools for use with various materials.

Machine tools

- ◆ Lathe

- ◆ NC wire discharge machine

- ◆ CNC jig grinder

- ◆ Precision lathe

- ◆ Small-hole electric discharge machine

- ◆ CNC internal grinder

- ◆ NC lathe

- ◆ Engraving electric discharge machine

- ◆ Ultra-precision aspherical surface processing machine

- ◆ Milling machine

- ◆ Surface grinder

- ◆ Lapping machine

- ◆ NC milling machine

- ◆ Rotary grinder

- ◆ Vacuum furnace

- ◆ Machining center

- ◆ Cylindrical grinder

- ◆ Precision machining center

- ◆ Forming grinder

- ◆ CNC jig borer

- ◆ Compound grinder

- ◆ NC electric discharge machine

- ◆ Profile grinder

Measurement devices

- ◆ World's highest level three-dimensional measuring instrument (Carl Zeiss: UPMC 850-CARAT-Ultra)

- ◆ Three-dimensional measuring instruments

- ◆ Contact roughness measuring instrument

- ◆ Ultra high precision three-dimensional measuring instrument (UA3P)

- ◆ Three-dimensional shape measuring instrument

- ◆ Laser length measuring machine

- ◆ Electron microscope (SEM)

- ◆ Image size measuring instrument

- ◆ Laser microscope

- ◆ Atomic force microscope (AFM)

- ◆ Roundness measuring instrument

- ◆ Hardness tester

- ◆ Industrial X-ray CT system

PRODUCTS

Inquiry by telephone:+81-47-386-3111

(Industrial machinery - Sales manager)

Mon~Fri 8:30~17:30

PAGE TOP

Component processing

Component processing Precision measurement

Precision measurement Ultra-high precision molds

Ultra-high precision molds