Industry Facts

PRODUCTS

Company Profil movie(1 minutes version)

Company Profil movie(5 minutes version)

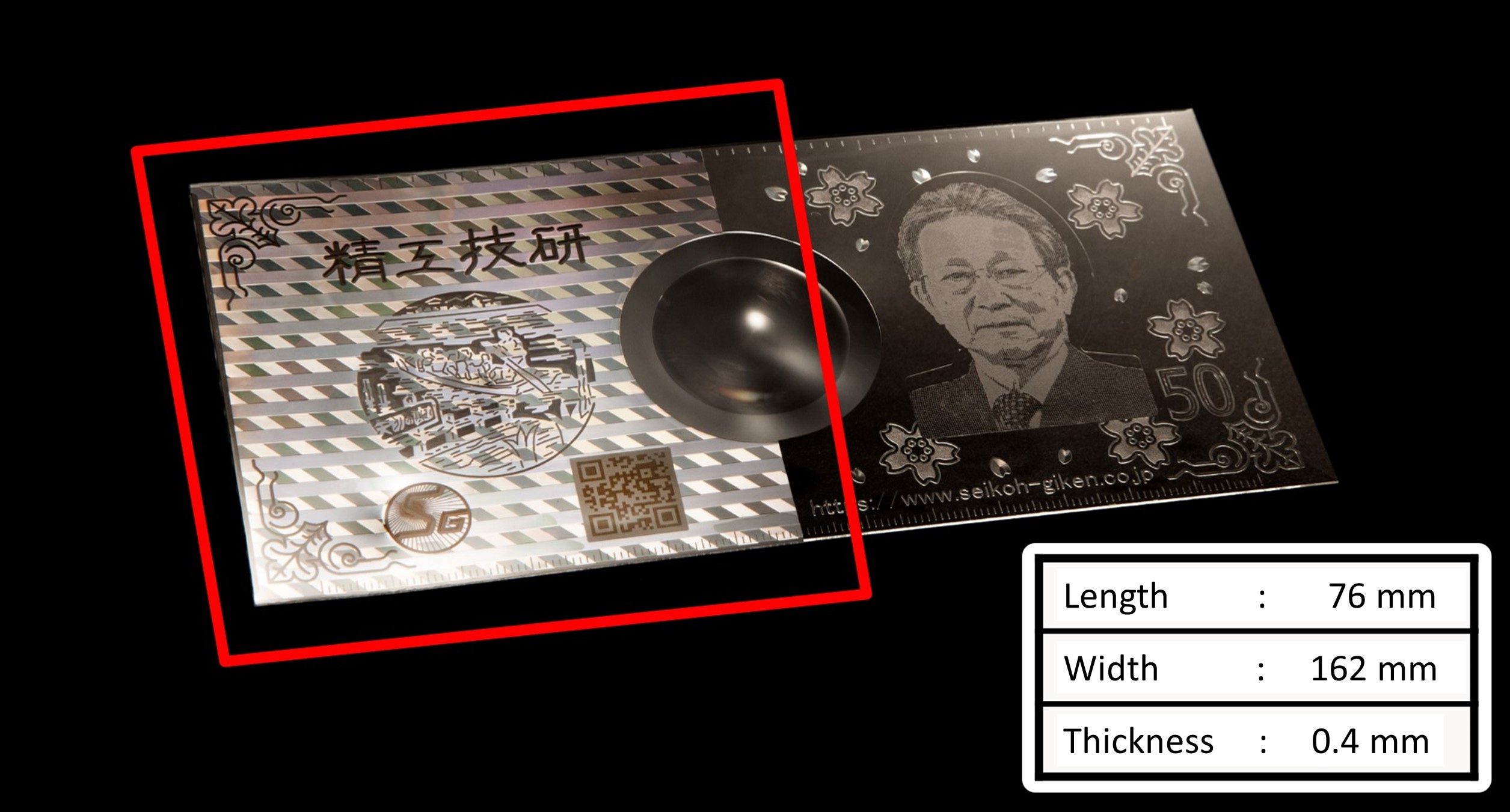

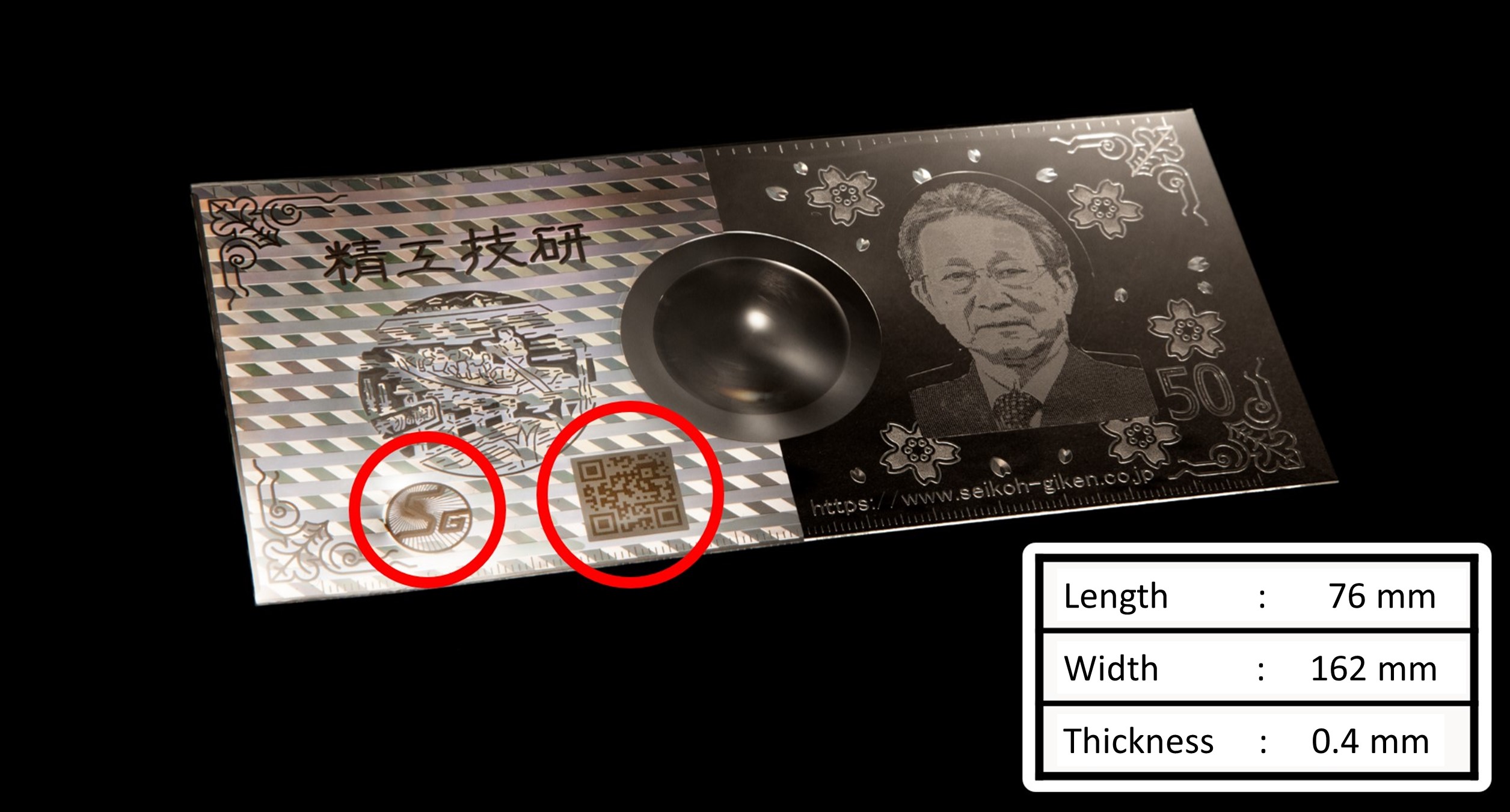

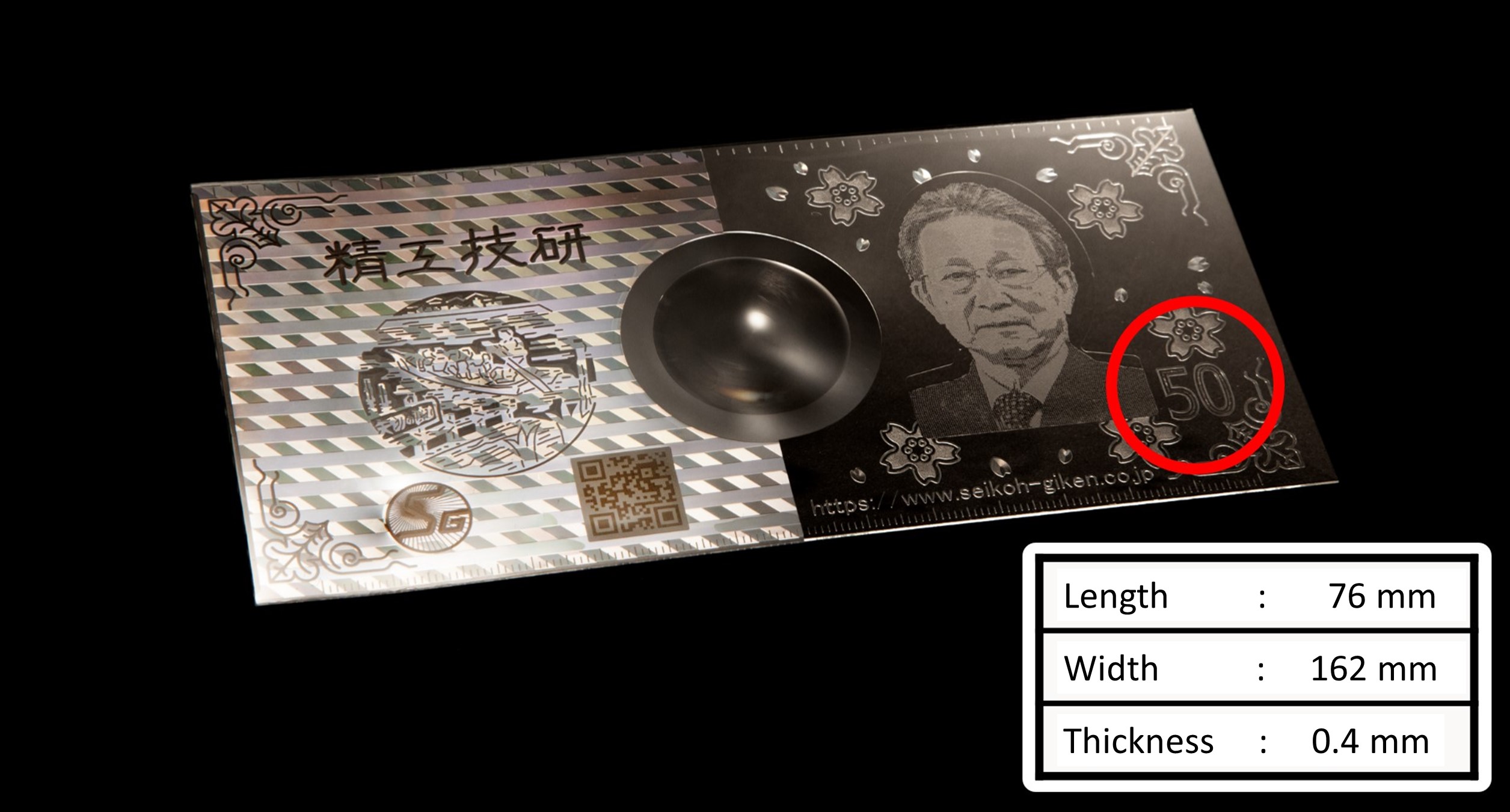

Technologies used in our 50th Anniversary sample

This is the sample mold we produced for our 50th Anniversary to introduce our technologies. This material will describe the technologies we used to create it.

* The designs we will introduce are all produced using our own processing machinery and molding machinery.

Contents

- Metallic tone decorative processing

- QR codes and gradation logos

- "Yakiri no Watashi" ferry river crossing (Matsudo City manhole design)

- Fresnel lens

- Portrait of the President and Chief Executive Officer with a highly transparent background (mirror finishing)

- Hidden characters created with ultra-precision processing

Metallic tone decorative processing

・ Metallic tone reproduction without the use of paint!

⇒ Contributing to the SDGs by not plating and painting!

The metallic tone is present immediately after molding, eliminating the need for secondary processing!

Products that apply this technology : various precision-molded products, decorations, diffractive optical elements (DOE)

V-grooves in three directions with different depths

(Pitch: 30 μm)

While normally the metallic tone can only be seen from one direction, by changing the height and angle of the V-grooves, the tone can be seen from all directions.(Patent acquired)

The technology is environmentally friendly: Products contain no volatile organic compounds (VOCs) found in paint because paint is not used, and they are highly recyclable because only a single resin material is used.

QR codes and gradation logos

・ QR codes and company logos are transferred to the transparent resin without post-processing!

⇒ Two colors with clear contrast are reproduced on a single resin!

Can create high-class designs that are difficult to produce with regular resin!

* A single-color background is required for QR code reading (ideally black).

The transparent part in the sample fully harnesses the polishing technology we have cultivated for 50 years and contributes to the contrast of the QR code.

The logo is also created with the best polishing technology in the industry, which ensures that the logo is not covered by the metallic tone and is clearly visible.

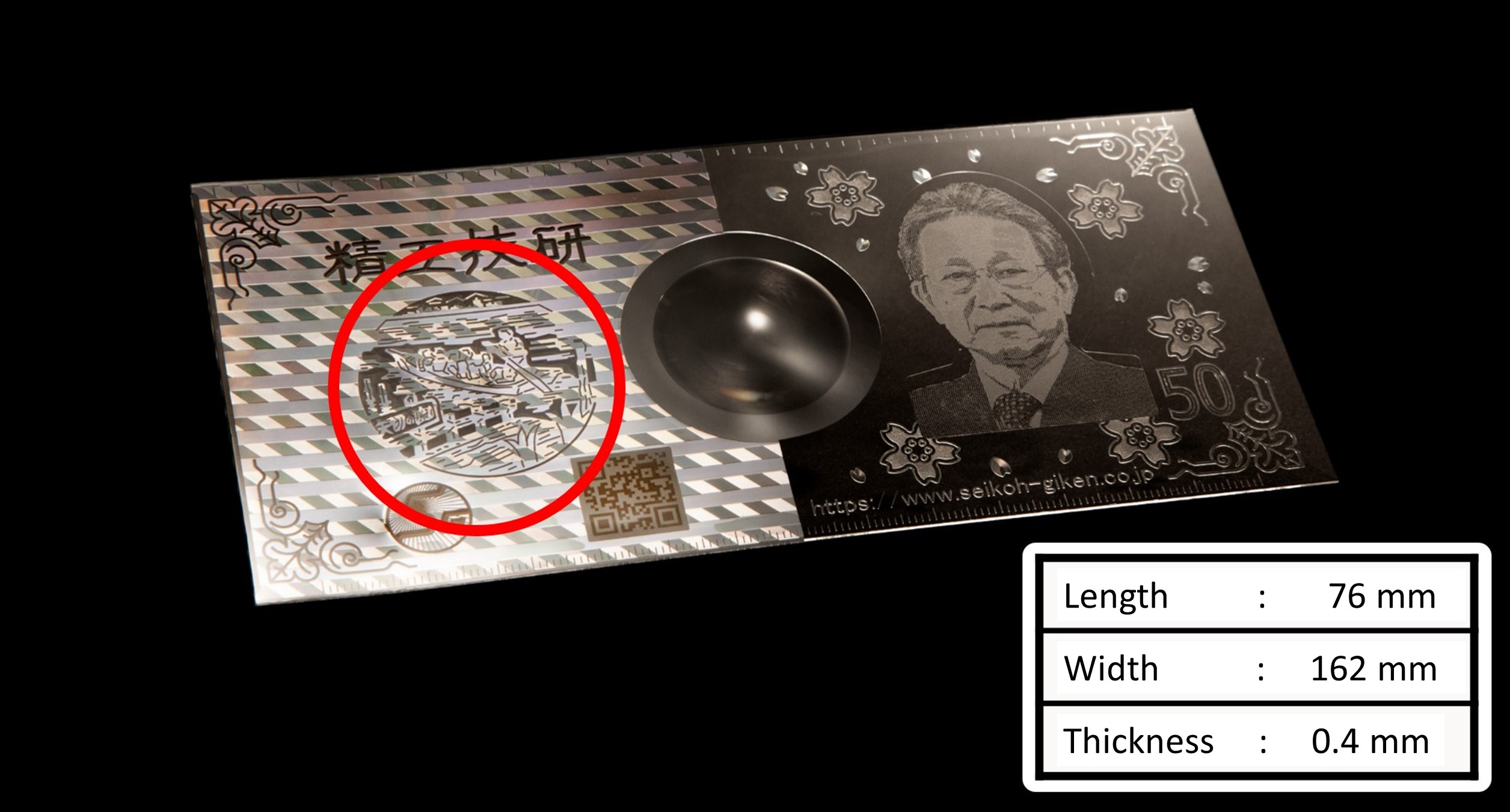

"Yakiri no Watashi" ferry river crossing (Matsudo City manhole design)

・ The intricate representation carefully utilizes straight lines and curved lines as well as the mirror surface and decorations!

⇒ We can also produce complicated patterns!

Sewage Fee Management Division of the Construction Department of Matsudo City Hall granted approval for us to use the Yakiri no Watashi design.

The manhole that it is based on was created to commemorate Matsudo City's 50th Anniversary and its achievement of a sewage coverage rate of 50%.

As we made the sample to mark our own 50th anniversary, and we are based in Matsudo City, we felt that the design was best choice.

Please visit the webpage below for more details on the design.

Manholes of Matsudo City

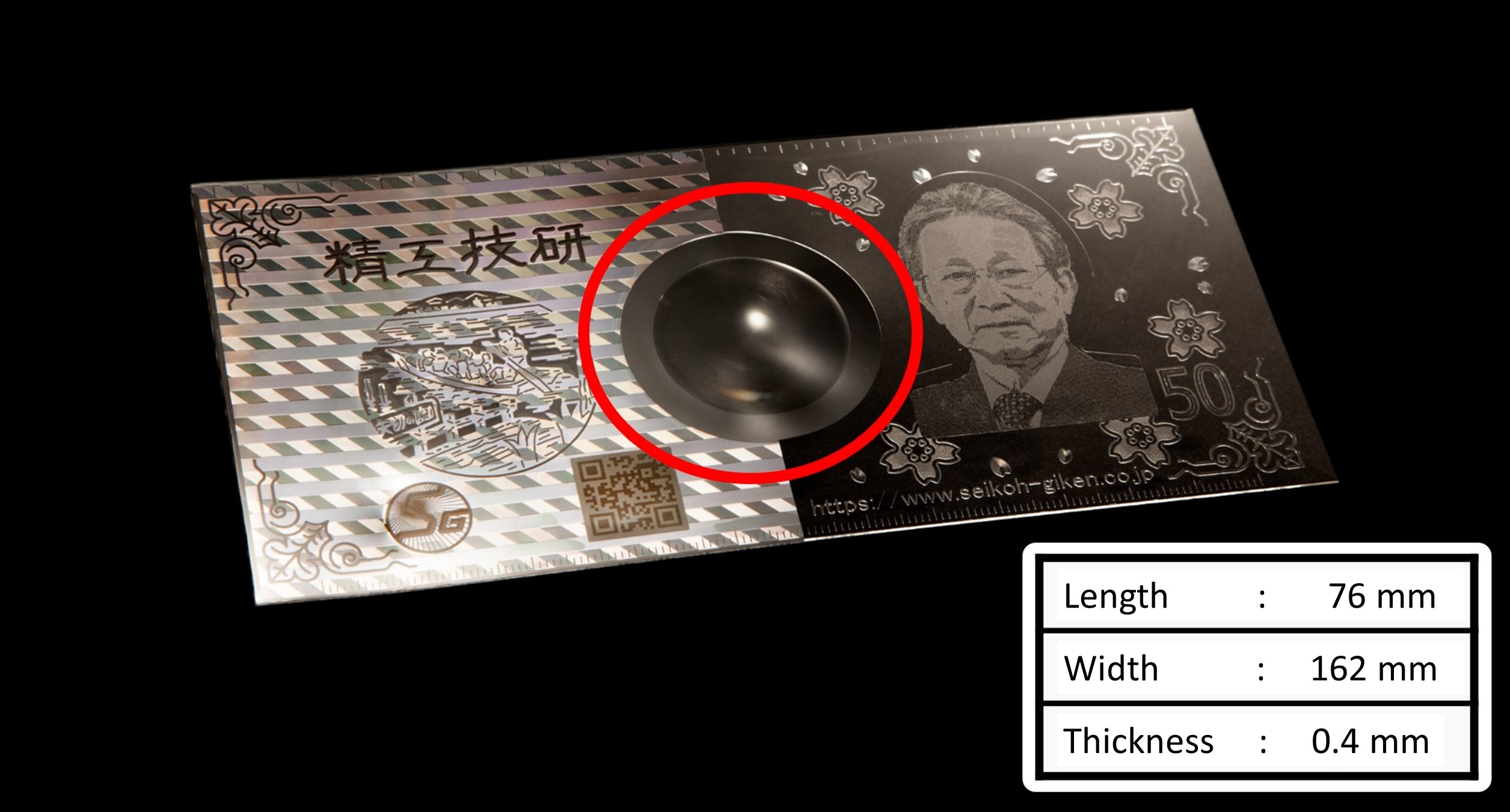

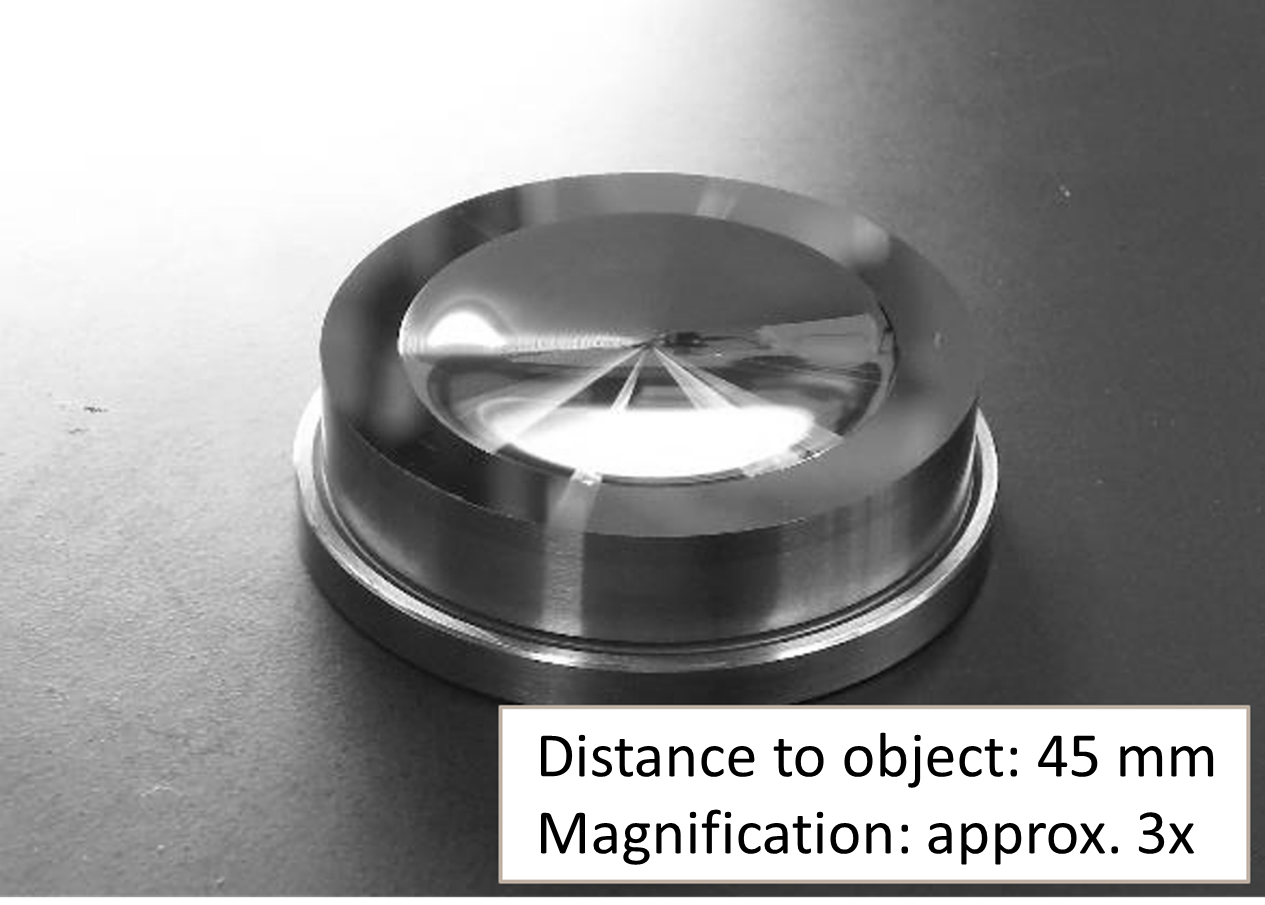

Fresnel lens

・ We can do optical designs in-house!

⇒We have a strong track record with a wide variety of lenses, including small diameter (Φ1.4 mm) and reflow-compatible (hybrid) lenses!

Products that apply this technology : lenses

Resin lenses are disposable because they are cheaper than glass lenses.Thanks to their small size and ability to be mass produced, they can be used for 3D sensing for home appliances and in fields such as medicine (endoscopic lenses).

Seikoh Giken can be contracted for optical design work.

Contact us.

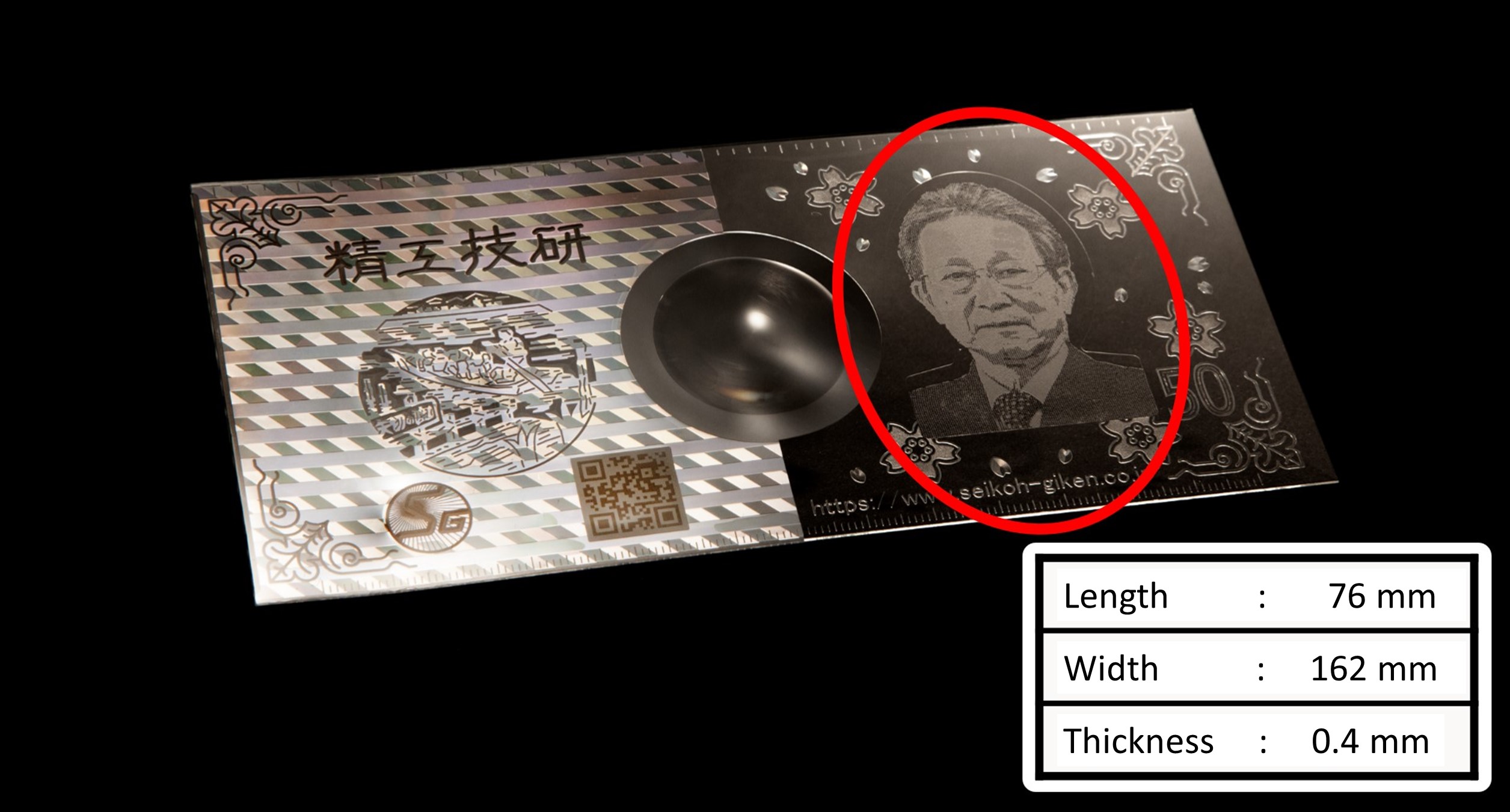

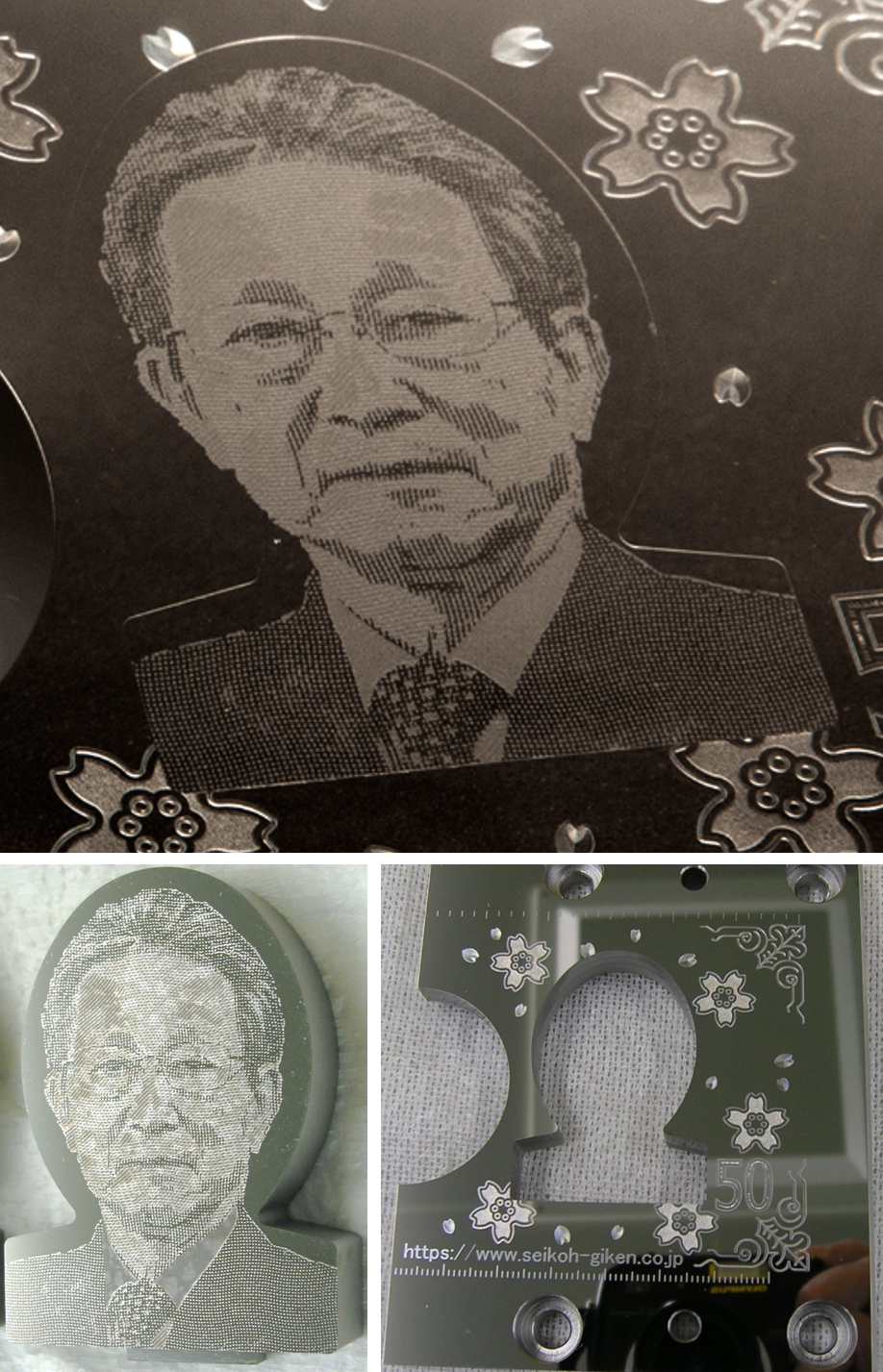

Portrait of the President and Chief Executive Officer with a highly transparent background (mirror finishing)

・New design method using laser processing!

⇒Outstanding laser design achieved with high-precision mirror finishing!

Products that apply this technology : processed components

The portrait's outline can become blurry as it is extremely difficult to transfer this sort of design.However, with our mirror surface polishing technique and micro-transfer technology, we can create a highly transparent background and transfer a clearly defined design.

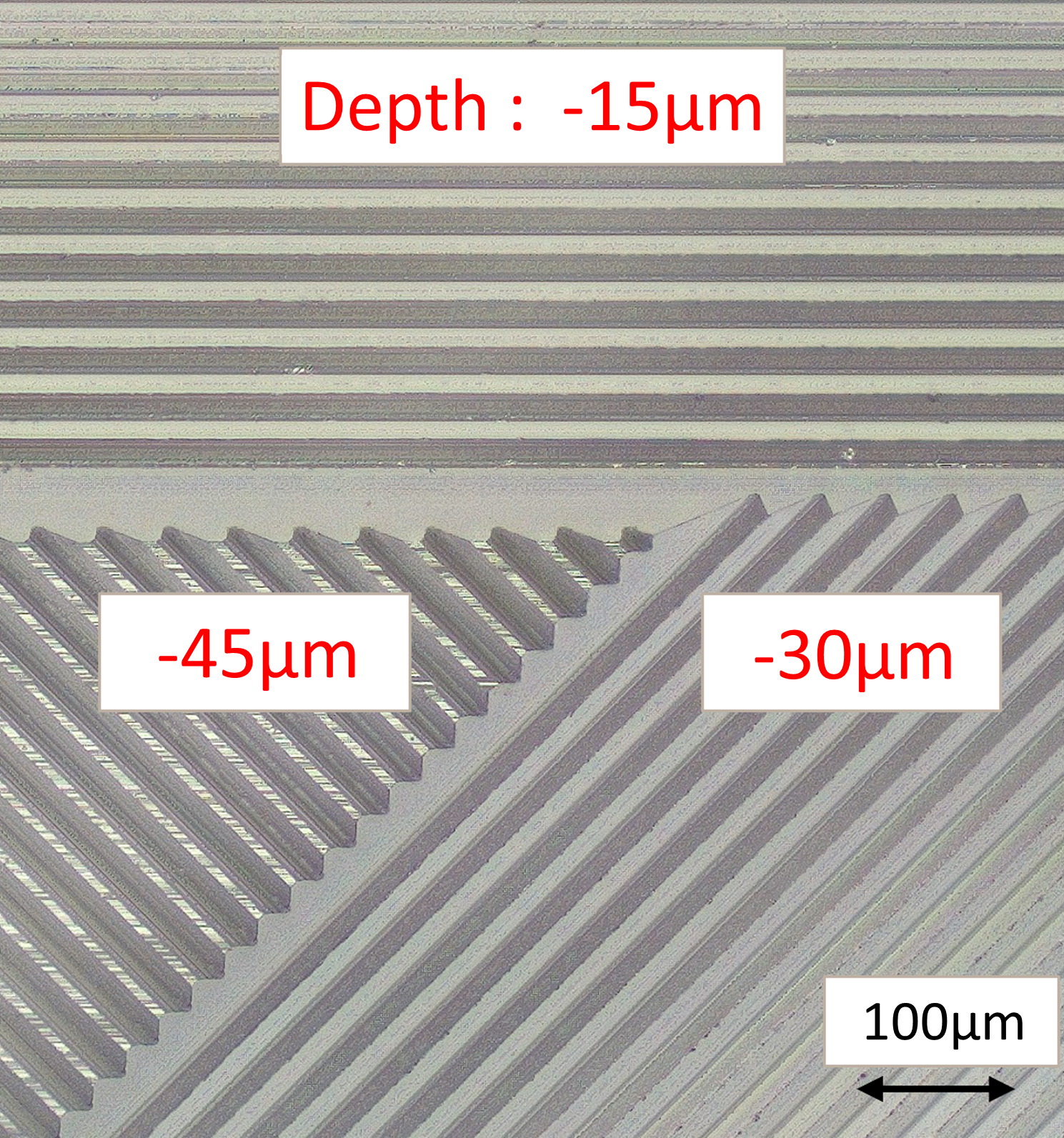

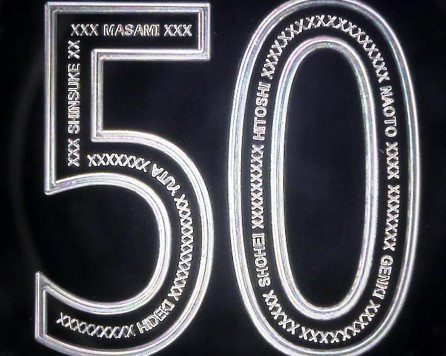

Hidden characters created with ultra-precision processing

・Hidden characters with a line width of 45 μm and a depth of 5 μm!

⇒We can mass produce ultra-precise molded products for medical or other uses!

Products that apply this technology : medical/biotechnology-related molded products

Hidden characters are used on actual notes to prevent fraud. They fully demonstrate the potential of micro-transfer technology.

The hidden characters on our sample, which have a line width of 45 μm and a depth of 5 μm, can only be produced with ultra-precision processing.

By using this technology, we have recently mass produced microchannel chips for medical use by using resin injection molding rather than using glass.

Please contact us if you have any inquiries about our microchannel chips.

To conclude

What did you think?

Seikoh Giken will continue to meet expectations though constant challenges and growth, as it has been doing for the last 50 years, working to contribute to social progress and development for the next 50 years to come.