PRODUCTS

Various precision-molded products, decorations, diffractive optical elements (DOE)

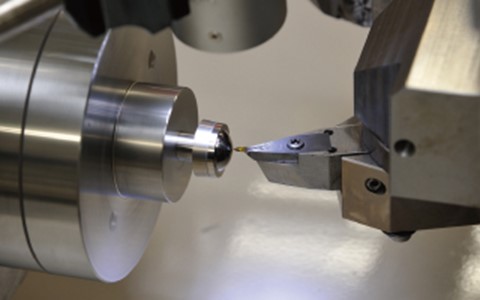

Seikoh Giken is a stable supplier of core parts such as micro-structure products and thin-walled molded parts.

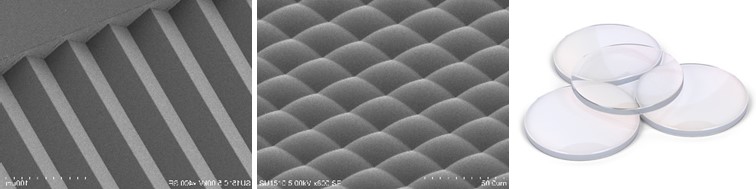

We use ultra-precise molds crafted in-house for mass production of molded products with complex shapes and thin walls. Seikoh Giken has developed technologies for transferring microscopic patterns with precision at the nano level by using injection compression technology, even when using normal mold clamping force and filling pressure. Utilizing low temperature molding technology, Seikoh Giken has achieved plastic injection molding of objects with a diameter of 120 mm and a wall thickness of 0.3 mm.

Precision molded products of all types

Adjustments to the mold structure helped suppress the occurrence of warping, allowing us to successfully establish a manufacturing method for molded products previously considered impossible with injection molding. "Smart cards" "Thin-walled packing" "Thin-walled plates" "Thin-walled vessels" etc.

VR, AR, MR, and optical molded products

VR (virtual reality), AR (augmented reality)

VR (virtual reality), AR (augmented reality)

Projections for demand regarding virtual spaces (metaverse) have brought more attention to VR (virtual reality) and AR (augmented reality) devices. There are growing expectations that our thin-wall molding and micro-transfer technologies will be able to help with issues like reducing product weight and improving safety.

With our proprietary mold and molding technologies, including support for future mass production, we will solve issues related to micro-structure transfer lenses (waveguides), glass substitutes (resin-based lenses), thin-walled light guide panes, substrates for aerial displays, transparent resin molded products, and birefringence compatibility.

Decoration technology

A molding/forming technology that can express color tones with a single injection molding process.

A molding/forming technology that can express color tones with a single injection molding process.

This technology is compatible with a range of transparent thermoplastic resins and offers varied color representation possible by adding design features.。

It does not require secondary processing such as vapor deposition, printing, or hot stamping, and we are proposing it as an environmentally friendly technology for new types of decorative expression.

(Patent acquired)

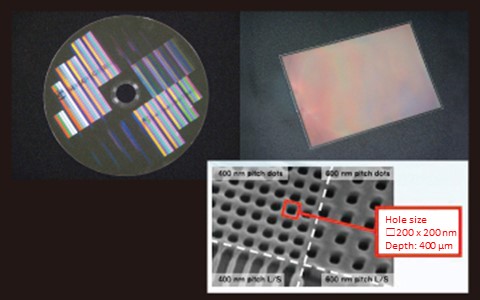

DOE (Diffractive Optical Elements)

Allow letters and patterns to be projected by shining a laser beam on a micro-patterned section.

Allow letters and patterns to be projected by shining a laser beam on a micro-patterned section.

A DOE is an optical element that makes use of diffracted light.

Inquiry by telephone:+81-47-386-3111

(Industrial machinery - Sales manager)

Mon~Fri 8:30~17:30

PAGE TOP