PRODUCTS

Lensed Fiber Assembly

- •Perfect for coupling fiber with LD's and PD's for various applications such as DFB lasers, pump lasers or receivers. Our high quality specialty pigtails will improve coupling efficiency, increase product performance and save your costs

- •We offer total solution for photonic packaging with our completed fiber to chip assemblies

Key Feature:

- •High precision fiber-end shaping

- •Multiple lens shapes are available for any application

- •High quality AR coating for various wavelengths

- •Kovar ferrules for welding and hermetic sealing

- •Low insertion loss terminations

- •Ni/Au metalization for exceptional solderability

Options

Fiber to the chip assemblies may include:

- •Fiber end-shaping

- •AR coating

- •Bare fiber metalization

- •Hermetic and welding ferrules

- •Low loss connector

- •Singlemode, Multimode, and PANDA fiber

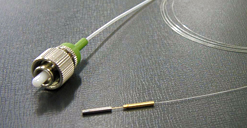

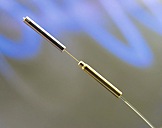

9FC/APC wedged fiber assembly for

980nm LD coupling

Welding and hermetic ferrules

Angled fiber-end

Wedged lens

Basic Configuration

♦AR Coating :

- •Ion assisted deposition

- •Low reflection

- •Reflection ratio less then 0.3%, typically 0.1%

- •High environmental stability

- •Various wavelengths available 980nm 1310nm 1480nm 1550nm

- •Single or broadband available

♦Metalization :

- •Sputtering or plating process

- •Ni based Au plating or sputtering

- •High level of hermeticity and pull strength

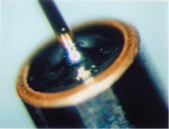

Soldering

♦Specifications

| Fiber Tip Shape | Wedge | Angle |

|---|---|---|

| Fiber Type | SMF28, Hl1060, PANDA, MMF | |

| Fiber Buffer O.D. | 250μm, 900μm | |

| Taper Angle | 90 deg | 0, 8, 45 deg |

| Lens Radius | 3-10μm | N/A |

| Metalization | Ni / Au | |

| Soldering & Hermeticity | Au/Sn ≦1x10-10 Pa・m3/sec ≦1x10-9 atm・cc/sec |

|

| AR Coating | 980, 1310, 1480, 1550± 20nm Reflection Ratio ≦ 0.3% |

|

| Adobe Reader is required to open the pdf files above. Click here to download a free copy. |