PRODUCTS

Interferometer

Interferometery Instrument

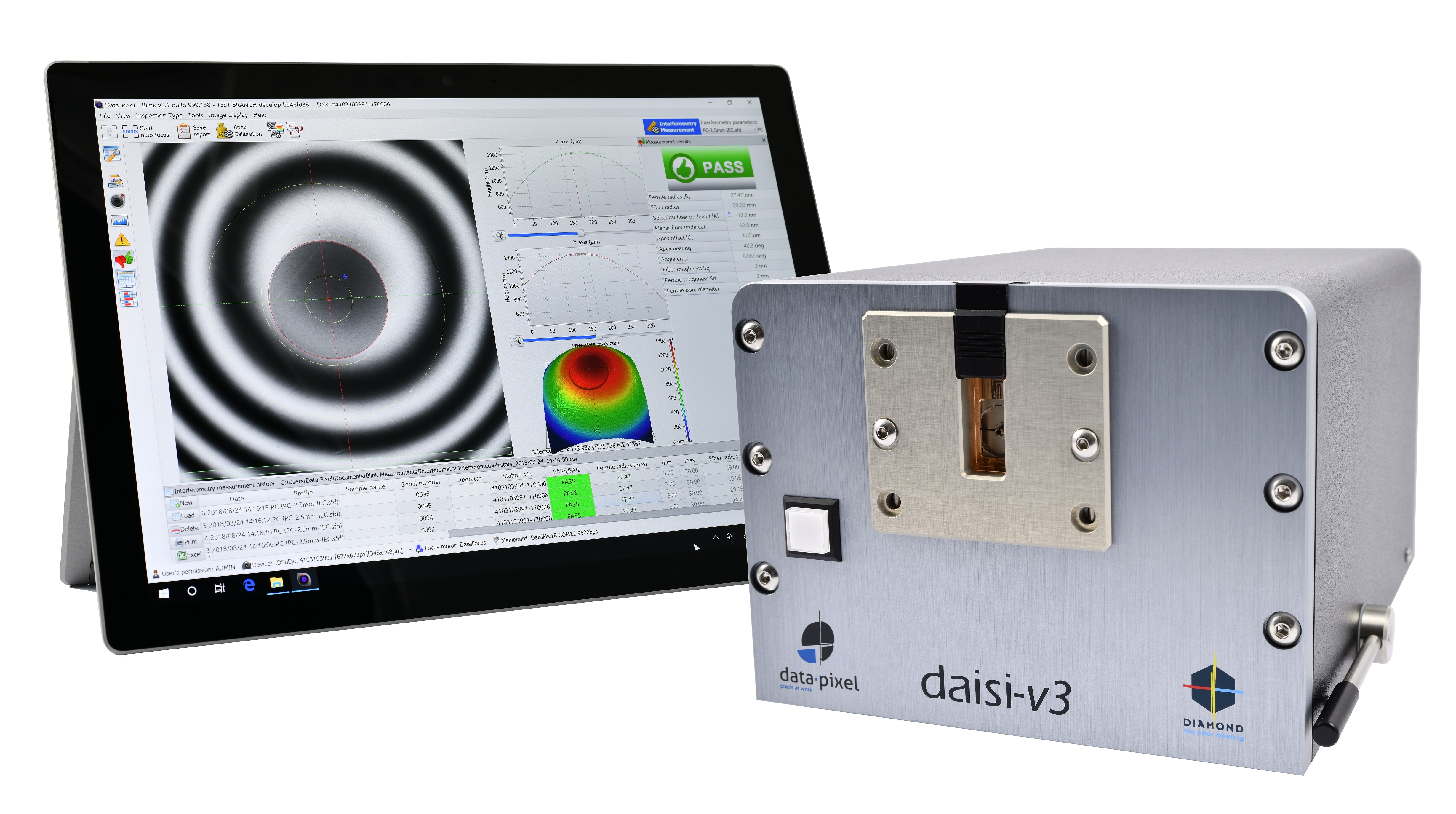

DAISI-V3

The ultimate production interferometer for measuring end-face geometry on single fiber connectors, equipped with a revolutionary « no-exterior-moving-parts » mechanical design.

The unit combines a x400 microscope and an interferometer in order to control connectors after polishing in a very short time. With the Blink software, operators have the easiest way to produce customised control reports. DAISI-V3 is fully compatible with Industry measurement Standards.

| Field of view (mm) : | 0.7 x 0.5 |

|---|---|

| Scan mode : | Red light |

| Radius (mm) : | 3 to flat |

| Apex Offset (μm) : | 0 to 500 |

| Fiber Height (nm) : | ± 160 |

| Fiber cleave angle (degrees) : | 0 to 12 |

| Measurement speed (sec.) : | 1 |

| Magnification : | X 400 |

| Output : | USB 2.0 x1, USB3.0 x1 |

| Power source : | External 12V |

| Dimensions HxWxL (mm): | 133x171x244 |

| Weight (kg) : | 6 |

DAISI-MT V3

The DAISI-MT (Digital Automated Interferometer for Surface Inspection) is a measuring instrument for multifiber connector end face geometry designed based on the same concept as the auto-focus, auto-calibration of DAISI.

The megapixel CCD used in this device achieves superior repeatability and reproducibility properties and rapid measuring speed. Moreover, because it is equipped with a USB 2.0 computer interface, like the DAISI it can be readily connected to a laptop computer.

| *Repeatability/Reproducibility | Range | |

|---|---|---|

| End face shear droop (mm) | 1% / 3% | 3 to flat |

| XY angle (°) | 0.002 / 0.02 | ±1° 0°(PC) or 8°(APC) |

| Fiber height (µm) | 0.005 / 0.015 | Up to 15 |

| Maximum measuring area (mm) | n/a | 3.2 × 2.5 |

※*Note: Repeatability and reproducibility Repeatability refers to the numerical value that can be consistently observed in measurements repeated 50 times without the connector being disconnected and reconnected, while reproducibility refers to the numerical value that can be consistently observed in measurements repeated 50 times with the connector being disconnected and reconnected for each measurement, with the value observed being 1Σ in both cases.

3DScope V2

The 3DScope V2 is a new geometry measuring device developed with the emphasis on measurement speed and accuracy as well as simplicity, durability, and cost.

Despite its small size, the 3DScope V2 comes with an auto-calibration function, achieves real-time, high-speed USB link transfer of uncompressed high-quality images, and delivers highly reliable measurements.

| *Repeatability/Reproducibility | Range | |

|---|---|---|

| Curvature radius (mm) | ±0.05% / ±0.05% | 3 to flat |

| Spherical eccentricity (µm) | ±0.5 / ±1 | 0 to 500 |

| Fiber draw-in (nm) | ±1 / ±1.5 | ±160 (±15 000 white LED options) |

※*Note: Repeatability and reproducibility

Repeatability refers to the numerical value that can be consistently observed in measurements repeated 50 times without the connector being disconnected and reconnected, while reproducibility refers to the numerical value that can be consistently observed in measurements repeated 50 times with the connector being disconnected and reconnected for each measurement, with the value observed being 1Σ in both cases.

Eccentricity Measurement Instrument

KONCENTRIK V2

Ferrule concentricity

+ index measurement

Patchcord concentricity

+ index measurement

Multi-functional system for test and measurement of fiber optic ferrules & cable assemblies

- ・Fast and automated measurements

- ・Measurement data exported in standard CSV format

- ・Easy calibration and simple Koncentrik software

- ・Magnification : x900 or x450

- ・Single Link Cable (USB2.0)

| Measured parameter(unit) | Range | Accuracy | |

|---|---|---|---|

| Connector Module |

Eccentricity(um) | 0 to 100 | ±0.15μm |

| Indexing(degrees) | 0 to 360 | Up to 1° | |

| Measurement speed(seconds) |

10+ (user variable) |

||

| Ferrule Module |

Eccentricity(um) | 0 to 100 | ±0.15μm |

| Indexing(degrees) | 0 to 360 | Up to 1° | |

| Ferrule outside Ø (mm) | 1 to 4 | ||

| Ferrule bore Ø (um) | 5 to 500 | ||

| Measurement speed(seconds) |

3+ (user variable) |

Insertion Loss / Return Loss Measuring Instrument

MAP-200 / mORL Module

♦Insertion loss / return loss measuring instruments manufactured by Viavi Solutions Inc.

The MAP Platform is a general-use measuring instrument with integrated modules enabling various kinds of measurements.

A single slot of the insertion loss / return loss measuring module mORL offers up to four light sources (1310, 1490, 1550, 1625 nm) (SM), with insertion loss resolution display in units of ±0.001 dB. The mORL uses mandrel-free technology and delivers return loss measurements on jumpers as short as 70 cm up to 80 dB. Moreover, the use of switch modules enables simultaneous testing of up to 100 channels. When measuring MT/MTO the use of integrating spheres enables removing unevenness in sensitivity due to the positioning of the light sensitive element. The mORL offers a line-up of various other modules including a multifiber measurement module.

| Insertion loss measurement | Measurement tolerance | ±0.02dB | |

|---|---|---|---|

| Switch use tolerance | ±0.01dB | ||

| Integrating sphere use tolerance | ±0.03dB | ||

| Return loss measurement | Reproducibility | Tolerance | |

|---|---|---|---|

| -30 to 65dB | ±0.1dB | ±1.0dB | |

| -65 to 70dB | ±0.2dB | ±1.0dB | |

| -70 to 75dB | ±0.4dB | ±1.7dB | |

| -75 to 80dB | ±1.5dB | ±3.0dB |

For inquiries concerning the specifications and other details of the above products, please contact Seikoh Giken directly.

Please feel free to inquire also about products not listed in the catalogue.

| Adobe Reader is required to open the pdf files above.Click here to download a free copy. |