PRODUCTS

Polishing Machine

- •The widest range of production polishers utilizing our proprietary turntable design

- •With our exclusive rotation-revolution mechanism, polishing films and polishing processes, and with over two decades of connector polishing expertise all contribute to the highest quality optical performance

U.S.Pat. No.4,979,334 / 5,351,445 / 6,165,055

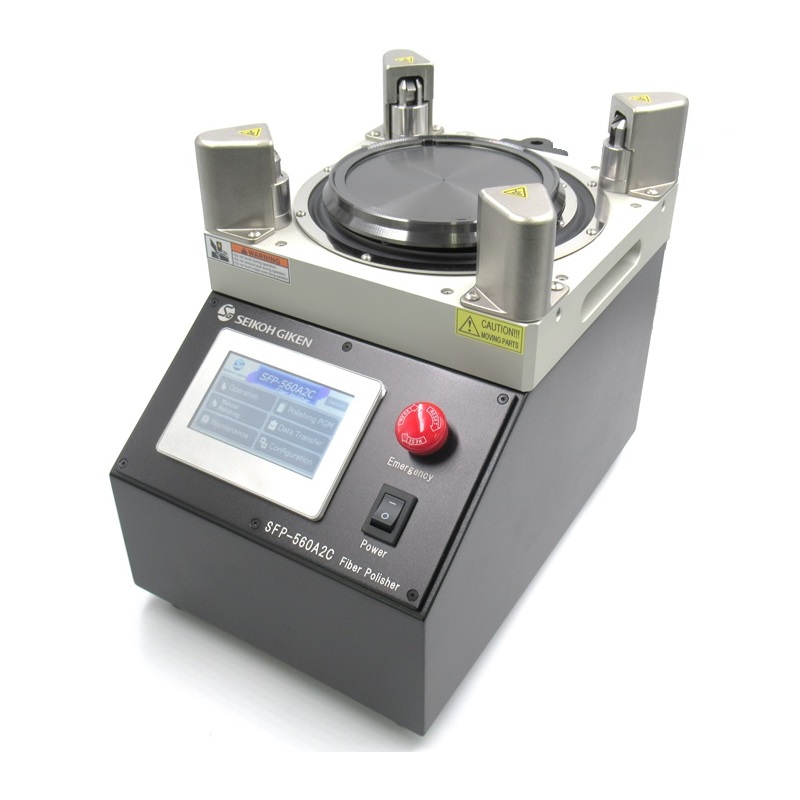

SFP-560A series (New)

The SFP-560A series fiber polisher is Seikoh Giken’s newest premium production polisher and the first in the marketplace to incorporate our patent pending Dynamic Pressure Control (DPC) pressurization system.

The unique DPC pressure technology offers a mass production platform incorporating highly stable, widely variable precision pressure control to the polishing Turntable. The pressure is applied from the bottom to the top. Moreover, SG’s advanced micro machining design guarantees polishing with perfect parallelism between the polisher's turntable and the rigidly clamped polishing holder by the 4 corners.

Combining proprietary bottom-up pressurization, precision speed & pressure control and rigid fixture parallelism, the SFP-560A series – while in DPC mode - realize epoxy removal of multi-fiber ferrule done by the SFP-560A series polisher and perform multi-fiber polishing similar in simplicity to standard single fiber connector polishing.

Incorporating the 4 Corner Clamp Post locking system from the Legacy SFP-550 series, the SFP-560A series polisher provides a wide range of benefits to the user ; 1) Backwards compatible with the full range of SFP-550 series IPC polishing holders*, 2) Open overhead work space for creative cable handling solutions for multi-fiber, large O.D cables.

Additional features include

1) Programmable polishing process up to 60* processes

2) Four (4) multi-timers for manual polishing operation

3) High Contrast, waterproof LCD Display with multi-language programming operation (ENG-CHN-SPN-JPN)

4) Selectable, password protected programming and operations modes for both administrators and users

5) Polishing program loading optional barcode scanner

6) Consumables info entry by barcode scanner

7) Operation and Maintenance Data metrics transfer via USB interface

8) Manages consumable information, change speed and pressure + ramp up time at each polishing step, and connect to a network

The following models are available for the SFP-560A series and both models are inclusive of all the above mentioned features.

| SFP-560A3 | Manual clamping levers |

| SFP-560A3C | Auto-clamping for less operator dependency |

* IPC fixture / holders are polished in IPC mode.

| Application | Mass production |

|---|---|

| Pressure Source | Pressurized air |

| Dimensions | W240xD370xH300mm |

| Weight | 22Kg |

| Input Voltage | 100-240 VAC, 50/60Hz |

| Polishing Capacity(maximum) | 72 |

| # of max programmable process | 48 |

| # of max steps in one process | 8 |

| Speed of Turntable | Rotation : 0.1-2.0rpm Revolution : 10-200rpm |

| Pressure Control | 2N to 200N (Approx. 0.5 to 45lb) in DPC mode |

| Connector Type | φ2.5mm PC, APC φ1.25mm PC, APC MT, mini-MT, Fiber Array |

OFL-15A

This model also offers excellent production throughput capability with up to 24 ferrules polishing simultaneously. Extremely versatile, the OFL-15A can polishing both connectors, ferrules and MT ferrules. It features a LCD touch panel for easy programming of various connector polishing processes which offers ease of operation.

Additionally, it features an active polishing pressure control through it's closed-loop load-cell sensor and stepping motor. This combination provides excellent polishing results while exceeding industry specifications for geometry performance.

| Application | High volume production |

|---|---|

| Pressure Source | Stepping motor with load-cell sensor |

| Polishing Capacity (maximum) | 24 |

| Programmable Process Steps | 5 (maximum) |

| Number of Programs | 15 |

| Speed of Turntable | Revolution: 100~280rpm |

| Dimensions | 240×390×510mm |

| Weight (approx.) | 30kg (63lb) |

| Input Voltage | 100/115/220/240 VAC, 50-60Hz |

| Connector Type | φ2.5mm PC, APC φ1.25mm PC, APC MT, mini-MT, Fiber Array |

SFP-550S3 has been discontinued.

SFP-550S3 has been discontinued.

Please consider SFP-560A3C as its successor machine.

Repair service and sales of maintenance parts will continue.

The replacement machine, SFP-560A3C, is a more advanced version of the SFP-550S3, which has not only consumable info management but also offers more advanced controls in time, speed and pressure with active pressure capability that you can expand range of polishing applications to include large O.D. cables polishing, MT and Fiber array.

Please contact our distributors and sales offices for more details.

SFP-550E3

The SFP-550E3 Polisher Series is Seikoh Giken's mid-range polisher offering a competitive priced, high volume programmable mass production model under our recently introduced concept "Ez-Maintenance and High Duty Cycle" series. Compared to the previous SFP-550 series, there is drastic improvement in ease of maintenance and machine robustness that has achieved reduction in maintenance cost (90% less per our internal test).

Unlike the previous model SFP-550E which had 4 individual timers, this new model SFP-550E3 features Multi Timer on LCD Touch Panel (4 timers). In addition, it features simplified polishing process programming (8 steps each x 12 processes). Polishing speed is variable from 70rpm to 200rpm for revolution and rotation speed is automatically adjusted as per revolution speed.

A notable feature of this polisher series provides the option to add a Center Pressure Module, which converts this machine to be used as an advanced multi fiber polisher.

(Note: the Center Pressure Module can be mounted to all SFP-550 series).

Polishing holders, films and pads are compatible among all 550 (120A) series

| Application | Mass production |

|---|---|

| Pressure Source | 4 coil springs |

| Dimensions | W260~D320~H290mm |

| Weight | 18.5kg |

| Input Voltage | 100-240 VAC, 50/60Hz |

| Polishing Capacity(maximum) | 48 |

| # of max programmable process | 12 |

| # of max steps in one process | 8 |

| Speed of Turntable | Rotation : 0.7-2rpm (auto) Revolution : 70 - 200rpm |

| Connector Type | φ2.5mm PC, APC φ1.25mm PC, APC MT, mini-MT, Fiber Array |

SFP-550C

The SFP-550C Polisher Series is Seikoh Giken's entry level mass production model. The 550C series model was also developed under the recently introduced concept of "Ez-Maintenance and High Duty Cycle" series. And, compared to the previous SFP-550 series, there is dramatic improvement in the ease of maintenance and machine robustness that has achieved reduction in maintenance cost (90% less per our internal test).

The addition of the high speed turntable technology allows the SFP-550C model to increase productivity by more than 20% (according to our internal test) over previous entry level polishers.

All Seikoh Giken polishing holders come equipped with the proprietary IPC (Individual Pressure Control) system that provides even pressure to each ferrule regardless of it's protrusion length while achieving stable and high-quality output.

Efficient large scale mass production lines focused on cost/production savings can be established by installing this combination of polishing machine and IPC holder for each polishing step.

| Application | Mass production |

|---|---|

| Pressure Source | 4 coil springs |

| Polishing Capacity(maximum) | 48 |

| Dimensions | W250×D305×H240mm |

| Weight (approx.) | 16kg |

| Input Voltage | 100-120 VAC, 50/60Hz or 220-240 VAC, 50/60Hz |

| Connector Type | φ2.5mm PC, APC φ1.25mm PC, APC MT, mini-MT, Fiber Array |

SFP-70D

This model is intended for light production capacity. The SFP-70D provides 6 axis simultaneous polishing and can be operated on AC or DC power for field use. Optional adhesive heaters are also available which can be attached to the polishing machines.

| Application | Laboratory |

|---|---|

| Pressure Source | 4 coil springs |

| Polishing Capacity(maximum) | 6 |

| Dimensions | 130×145×130mm |

| Weight(approx.) | 3.2kg |

| Input Voltage | 100-240VAC, 50/60Hz 3way power supply : 12V battery, Cigarette lighter socket and A/C power |

| Connector Type | φ2.5mm PC, APC φ1.25mm PC, APC |

SFP-70D2

This model provides 2 axis simultaneous polishing at competitively low cost and is most suitable for light production environments like field termination and laboratory use.

| Application | Laboratory |

|---|---|

| Pressure Source | Holder weight |

| Polishing Capacity (maximum) | 2 |

| Dimensions | 120×115×90mm |

| Weight (approx.) | 3.2kg |

| Input Voltage | 100-240 VAC 50/60Hz |

| Connector Type | φ2.5mm PC&APC φ1.25mm PC&APC MT/PC&APC |

For inquiries concerning the specifications and other details of the above products, please contact Seikoh Giken directly.

Please feel free to inquire also about products not listed in the catalogue.

| Adobe Reader is required to open the pdf files above. Click here to download a free copy. |